What is the difference between iron and iron ore?

Though iron is found abundantly, it is not found independently. It is found in the form of its oxides in the underground rocks, these are called as iron ores. Iron ore suppliers extract this iron from the underground and they refine the ore to get pure iron. Iron ore looks totally different from the pure iron.

Iron is one of the most common elements on earth. … Iron ore is converted into various types of iron through several processes. The most common process is the use of a blast furnace to produce pig iron which is about 92-94% iron and 3-5% carbon with smaller amounts of other elements.

How is iron made from iron ore?

The production of iron from its ore involves an oxidation-reduction reaction carried out in a blast furnace. The iron found in iron ores are found in the form of iron oxides. … As a result of these impurities, iron must be first separated from the gangue and then converted to pure iron

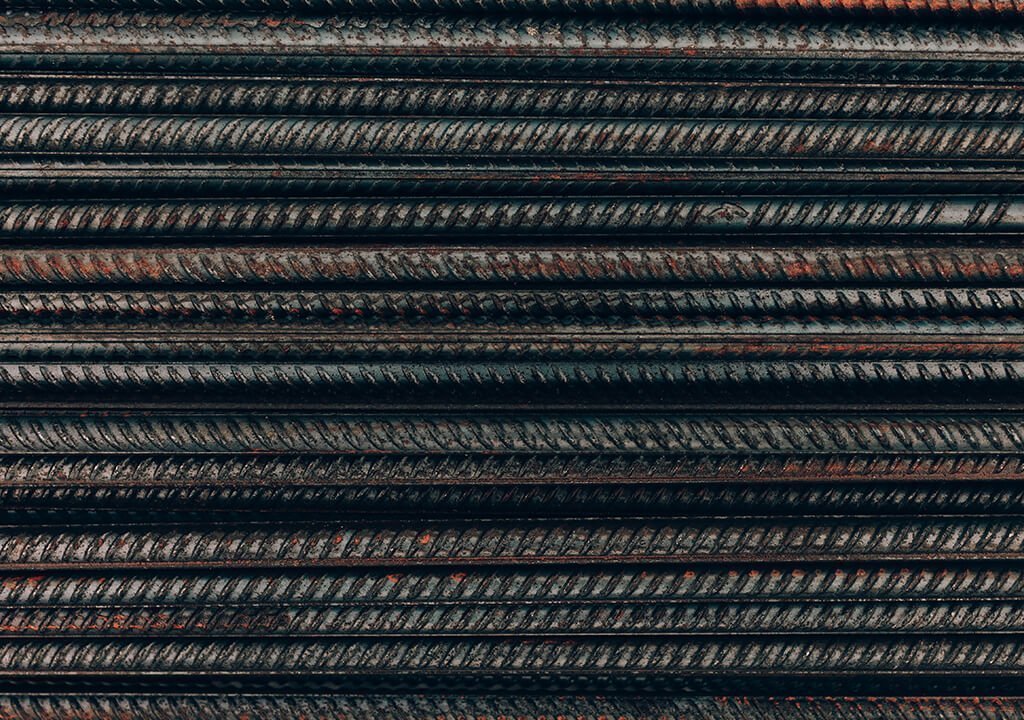

Carbon Steel Rebar

Carbon steel rebar is the most common type of rebar used in residential and commercial projects. This alloy steel is exceptionally cost-effective and durable, but the carbon steel may not hold up well to projects with high moisture exposure. Using carbon steel rebar may be risky if you work with high moisture content or in high-humidity areas.

Welded Wire Fabric (WWF) Rebar

Although this type of material has a different kind of name than other standard rebar types, WWF rebar is actually a grid pattern made of welded low-carbon steel wire. The grid can help reinforce concrete slabs to improve the overall tensile strength of the concrete.

Epoxy Coated Rebar

Epoxy-coated rebar works well in high-humidity and high-moisture construction projects. The rebar is coated with a thick epoxy, which helps to slow corrosion. Unfortunately, the delicate epoxy coating can become scratched and damaged during shipping, rendering the rebar much less effective against corrosion.

Stainless Steel Rebar

Although not as cheap as carbon steel rebar, stainless steel rebar can be a viable alternative. These steel reinforcing bars are used for bridges, roads, piers, and other weight-supporting structures. Unlike carbon steel rebar, stainless steel rebar can help prevent corrosion, giving you added protection.

Galvanized Rebar

One of the more expensive options, galvanized rebar, is an alloy steel rebar dipped in a zinc solution to add a special water coating that can deter corrosion. This material is an excellent alternative to epoxy-coated rebar. Galvanized rebar is 40 times more resistant to corrosion and holds up better during shipping and installation.

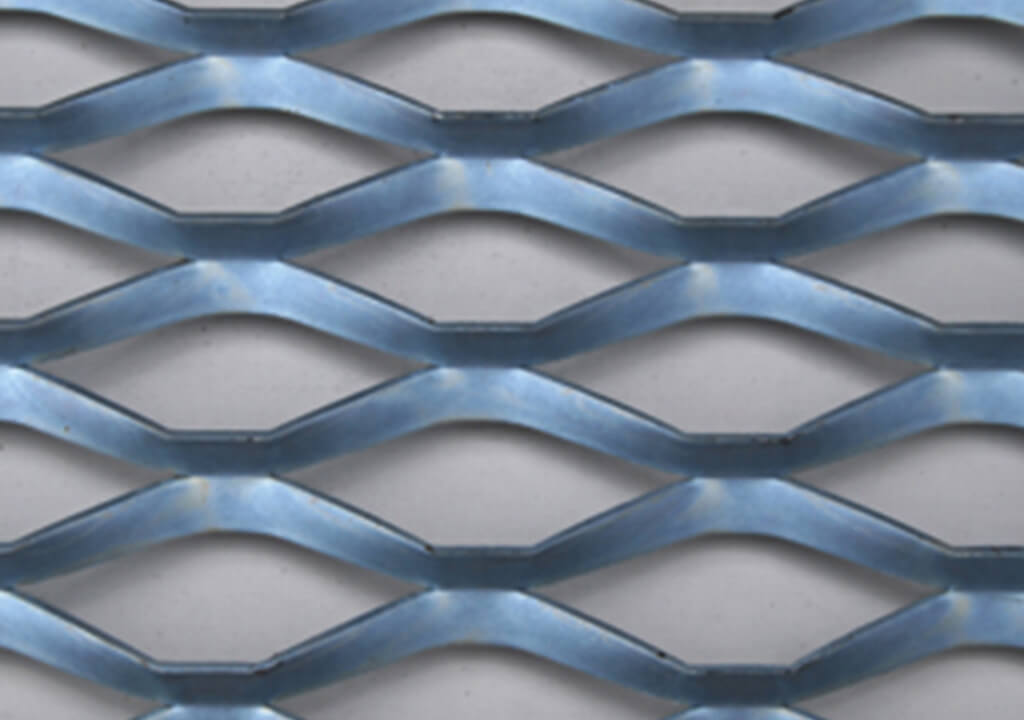

Expanded Metal Rebar

Similar to WWF rebar, expanded metal creates a metal mesh that is detailed in diamond-shaped lines. The mesh is made from a single steel sheet that is expertly cut and expanded. This material is commonly used when extremely thick plaster is needed to support the concrete. Expanded metal rebar is often used for sidewalks or walking surfaces, but it is not strong enough to withstand heavy vehicle traffic or heavy weights.

Iron Core

Iron Mine

Expanded Metal Rebar

Galvanized Rebar

Stainless Steel Rebar

Epoxy Coated Rebar

Welded Wire Fabric (WWF) Rebar